Multi Purpose Yellow Lubricating Lithium Grease

- HH

- SHANDONG

- 7-10 WORK DAYS

- DAILY OUT-PUT 10000KG

1. The product is made of new thickened high viscosity mineral lubricating oil with additives Grease.

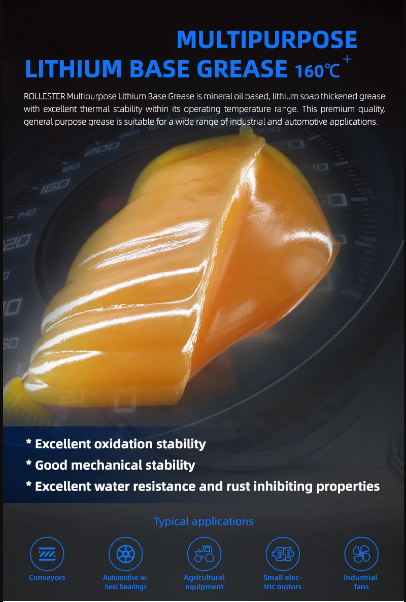

2. Excellent oxidation stability, water resistance, mechanical stability, and high temperature resistance different.

3. We cooperat with many big Automobile manufacturer like: VOLVO, DAIMLER, It is recognized for its excellent quality

4. Good quality funcation: Excellent oxidation stability, Good mechanical stability, Excellent water resistance and rust inhibiting properties

5. Lubrication of the conveyor system.

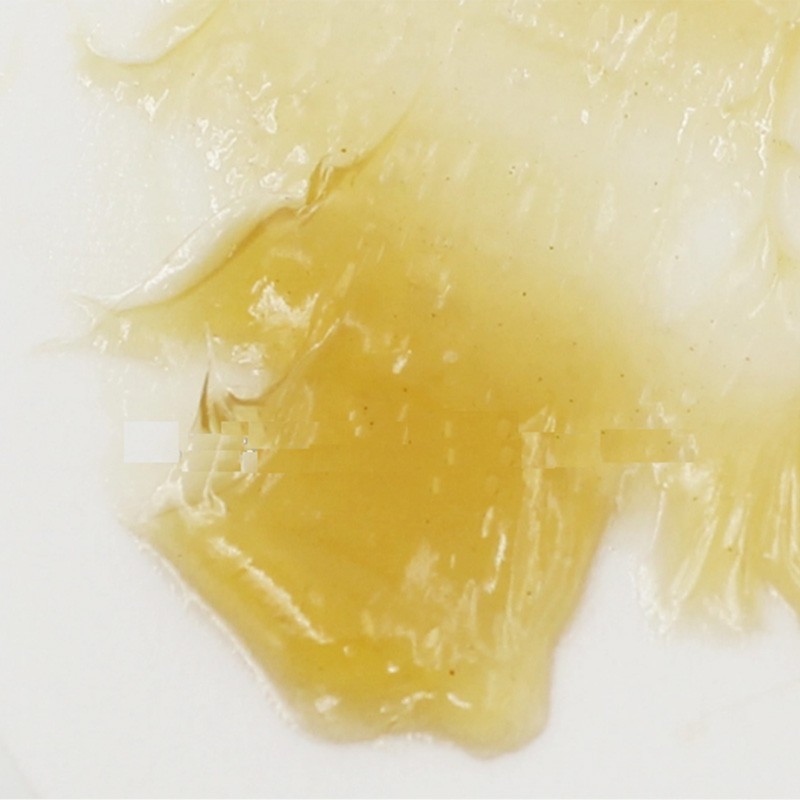

Iterm name: Multi Purpose Yellow Lubricating Lithium Grease

1. The product is made of new thickened high viscosity mineral lubricating oil with additives Grease.

2. Excellent oxidation stability, water resistance, mechanical stability, and high temperature resistance different.

3. We cooperat with many big Automobile manufacturer like: VOLVO, DAIMLER, It is recognized for its excellent quality

4. Good quality funcation: Excellent oxidation stability, Good mechanical stability, Excellent water resistance and rust inhibiting properties

5. Lubrication of the conveyor system.

Quick Details | |||||||

Place of Origin | Shandong China | Application | Automotive Lubricant | Type | Greases | ||

General Composition | Base Oil | Drop point: | 180 Degree | Color | Transparent Yellow | ||

Worked Cone Penetration, 0.1mm | 220 to 250 | MOQ | 1 Ton | Appearance | Smooth | ||

Quality | Excellent | Certificate | ISO9001:2008, SGS | Delivery Time | 10-15 Days | ||

Supply Ability | 50000 Metric Ton/Metric Tons per Year | Port

| Qingdao port | ||||

Packaging Details | 300g~390g cartridge ,500g plastic tub ,1kg Tin ,15kg pail 180kg metal drum | ||||||

Lead Time | Quantity(Kilograms) | 1 - 15000 | >15000 | ||||

Est. Time(days) | 7 | To be negotiated | |||||

Technical Data Sheet

NLGI consistency calss | 2 | 3 | |

Soap type | Lithium | Lithium | |

Color | Yellow | Amber | |

Base oil type | Mineral | Mineral | |

Dropping point DIN ISO 2176 | >180℃ (>355℉) | >180 °C (>355 °F) | |

Base oil viscosity |

|

125 12 | |

Worked penetration DIN ISO 2137 |

|

220-250 280 max. | |

Mechanical stability |

|

295max. 'M' | |

Corrosion protection | |||

Emcor: | -standard ISO 11007 | 0-0 | 0-0 0-0 |

Water resistance | |||

DIN 51 807/1, 3hrs at 90℃ | 1 max | 1 max. * | |

Oil separation | |||

DIN 51 817, 7 days at 40℃, static,% | 1-6 | 1-3 | |

Lubrication ability | |||

R2F, running test B at 120℃ | Pass | Pass | |

Copper corrosion | |||

DIN 51 811 | 2 max. At 110℃ (230) | 2 max. At 110℃ (265℉) | |

*Typical value | |||

Colors and specifications can be Customized | |||