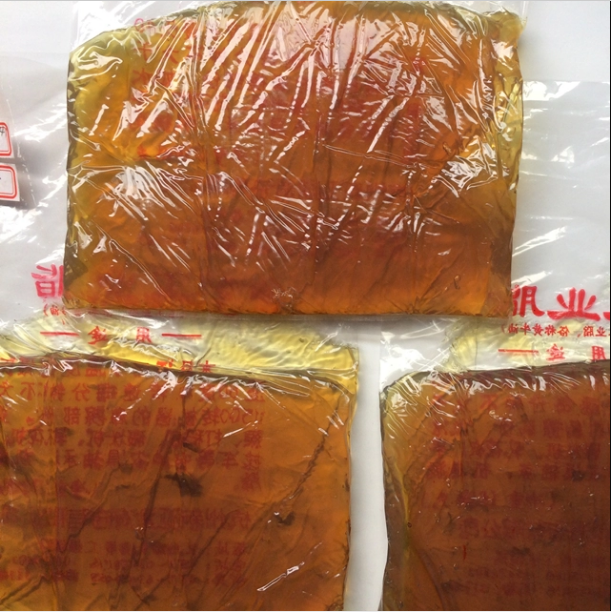

Machinery Yellow Lubricant Industrial Base Grease

- HH

- SHANDONG

- 7-10 WORK DAYS

- WEEKLY OUT-PUT 10000KG

1. This product is made of hydroxy fatty acid lithium soap thickened mineral oil and is a multi-effect, long-life grease.

2. It has excellent performance of heat resistance, anti-friction, water resistant as well as anti-oxidize and adheaiveness.

3. Widely used in industrial equipments, all kinds of cars, buses, trucks and bearings. Application environment varies from -20°C-220°C.

4. Our produce also suitable for high speed, heavy load and other harsh conditions, cars, trucks and heavy trucks, etc.

Iterm name: Machinery Yellow Lubricant Industrial Base Grease

1.This product is made of hydroxy fatty acid lithium soap thickened mineral oil and is a multi-effect, long-life grease.

2. It has excellent performance of heat resistance, anti-friction, water resistant as well as anti-oxidize and adheaiveness.

3. Widely used in industrial equipments, all kinds of cars, buses, trucks and bearings. Application environment varies from -20°C-220°C.

4. Our produce also suitable for high speed, heavy load and other harsh conditions, cars, trucks and heavy trucks, etc.

Quick Details | |||||||

Place of Origin | Shandong China | Application | Automotive Lubricant | Type | Greases | ||

General Composition | Base Oil | Drop point: | 180 Degree | Color | Transparent Yellow | ||

Worked Cone Penetration, 0.1mm | 220 to 250 | MOQ | 1 Ton | Appearance | Smooth | ||

Quality | Excellent | Certificate | ISO9001:2008, SGS | Delivery Time | 10-15 Days | ||

Supply Ability | 50000 Metric Ton/Metric Tons per Year | Port

| Qingdao port | ||||

Packaging Details | 300g~390g cartridge ,500g plastic tub ,1kg Tin ,15kg pail 180kg metal drum | ||||||

Lead Time | Quantity(Kilograms) | 1 - 15000 | >15000 | ||||

Est. Time(days) | 7 | To be negotiated | |||||

Technical Data Sheet

NLGI consistency calss | 2 | 3 | |

Soap type | Lithium | Lithium | |

Color | Yellow | Amber | |

Base oil type | Mineral | Mineral | |

Dropping point DIN ISO 2176 | >180℃ (>355℉) | >180 °C (>355 °F) | |

Base oil viscosity |

|

125 12 | |

Worked penetration DIN ISO 2137 |

|

220-250 280 max. | |

Mechanical stability |

|

295max. 'M' | |

Corrosion protection | |||

Emcor: | -standard ISO 11007 | 0-0 | 0-0 0-0 |

Water resistance | |||

DIN 51 807/1, 3hrs at 90℃ | 1 max | 1 max. * | |

Oil separation | |||

DIN 51 817, 7 days at 40℃, static,% | 1-6 | 1-3 | |

Lubrication ability | |||

R2F, running test B at 120℃ | Pass | Pass | |

Copper corrosion | |||

DIN 51 811 | 2 max. At 110℃ (230) | 2 max. At 110℃ (265℉) | |

*Typical value | |||

Colors and specifications can be Customized | |||