Product Inspection Process

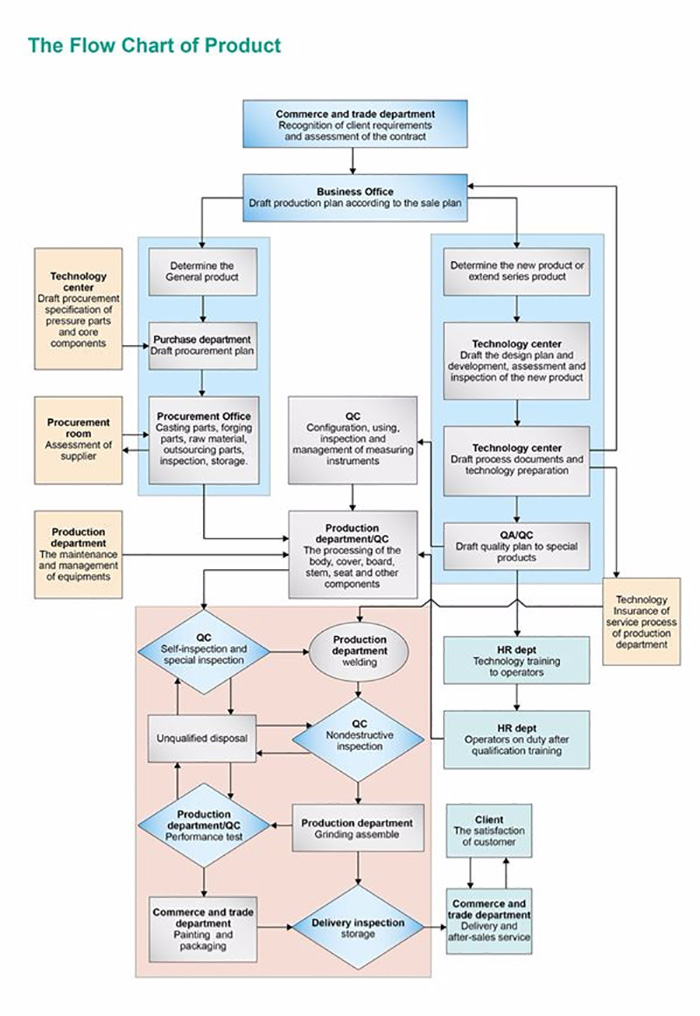

Product quality is the life of an enterprise, which is the way for every enterprise to survive. Although quality and low price can deceive people for a while, they will eventually be abandoned. Since our company started, we always put product quality first. Product quality inspection runs through the whole production process. Before coating production, we will proofread and test whether the pigment is consistent with the requirements of the customer's order. In the production process, we will randomly select the finished products, measure the thickness of the finished products, test the embossing effect of the finished products, and ensure that the finished products are coated and embossed evenly. After the order is completed, we will check the finished products again, and only the qualified products can enter the finished product warehouse. Before delivery and transportation to customers, all finished products will be subject to another quality inspection before delivery, so as to ensure that all outgoing products are qualified products with the required quality.

While strengthening the quality control in the production process, we have established a complete after-sales service system for goods. Each batch of our products has a production flow sheet during production, each process is clear and clear, and samples are kept. If the customer has any objection to the product quality, our after-sales service personnel will inform the quality control department of the customer's complaint as soon as possible, and the quality control department will immediately transfer the production flow sheet and check the production sample. If there is any problem, we will compensate the customer according to the company's after-sales quality system as soon as possible.